Customer

DeLoof Construction

Completion Year

2020

Description

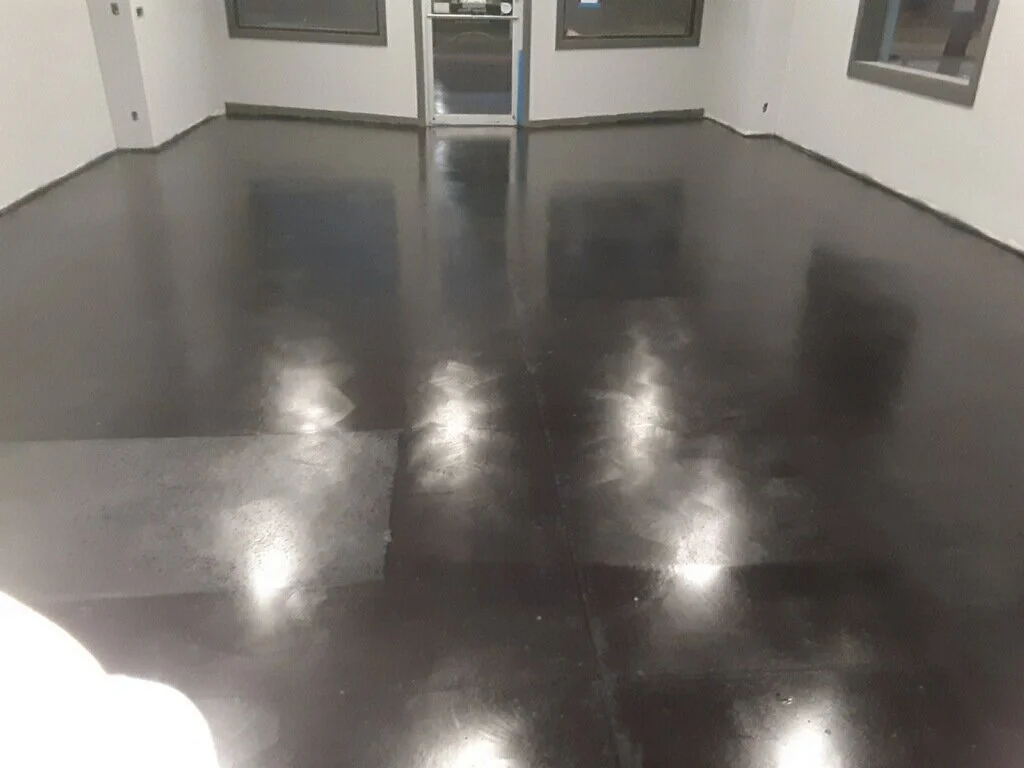

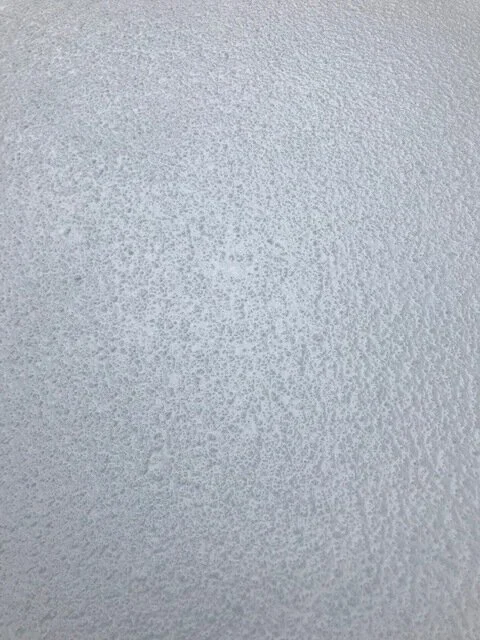

This project was an old break room with a VCT tile. All the tile was removed exposing some large holes and cracks in the concrete. These were patched with a combination of Epoxy patch materials and urethane cement. All patchwork was diamond ground to a smooth surface and a three-coat 100% solids epoxy coating with anti-slip was applied.