Customer

Schweitzer Construction

Completion Year

2020

Description

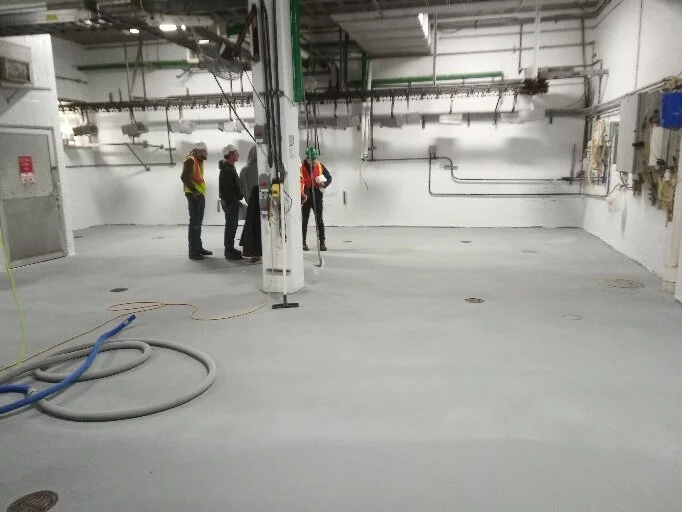

This was a 100-year-old building being converted into a new restaurant. In the dining area, we Diamond ground the concrete to remove all the old adhesives from the existing floor coverings. We used a large diamond grinder and went over the floor with 30 grit, filled all cracks, and patched all damage on the floor. We then continued to grind using 80 grit and 150 git diamonds to smooth the floor. Once all patching, crack filling, and grinding was done we stained the floor using an acetone concrete stain. This followed by applying a low gloss clear sealer. In the kitchen and back of the house, we performed diamond grinding, patching, and crack filling followed by applying a two-coat urethane cement coating.